Featured

![Sparsetral [MODEL RELEASE]](https://serp.ai/content/images/2024/02/--SERP-AI---Logo---min---landscape-min.png)

Sparsetral [MODEL RELEASE]

Introducing Sparsetral, a sparse MoE model made from the dense model mistral. For more information on the theory, here is the original paper (Parameter-Efficient Sparsity…

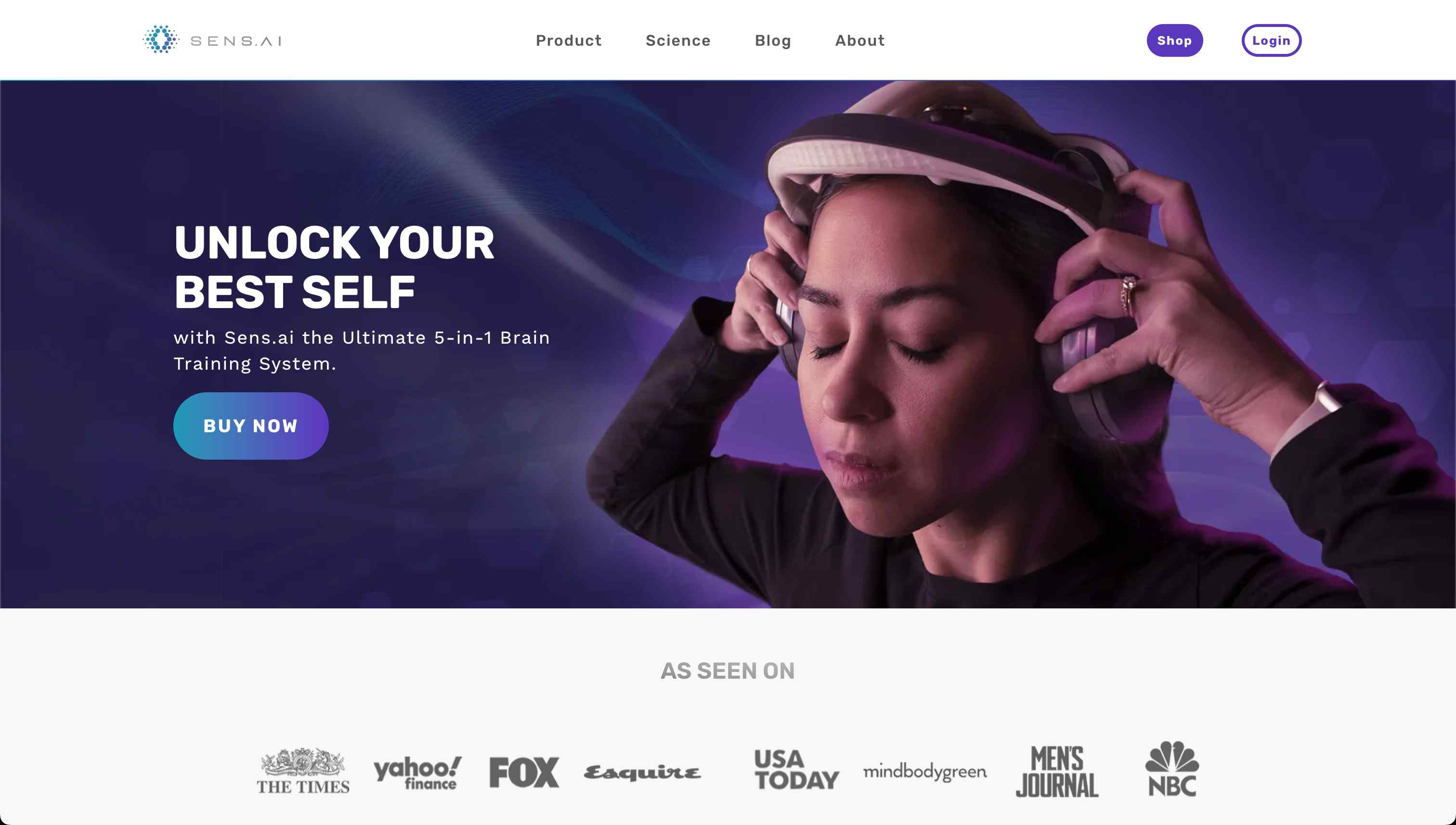

SENS.AI

Ladies and gentlemen, tech enthusiasts, and early adopters, today I'm thrilled to review the Sens.ai, a groundbreaking neurotechnology headset and gamified mobile app that's…

Airtable Subscriptions & Expenses Manager (Free)

Airtable Subscription Tracker

A simple tool designed to manage and monitor your subscription services with ease - for free.

Easy to update interface, built in…

Bulk AI DALL•E 3 Image Generations (One Click)

I know there's a lot of non-developers out there that just would like to be able to press the button and get bulk AI contact…

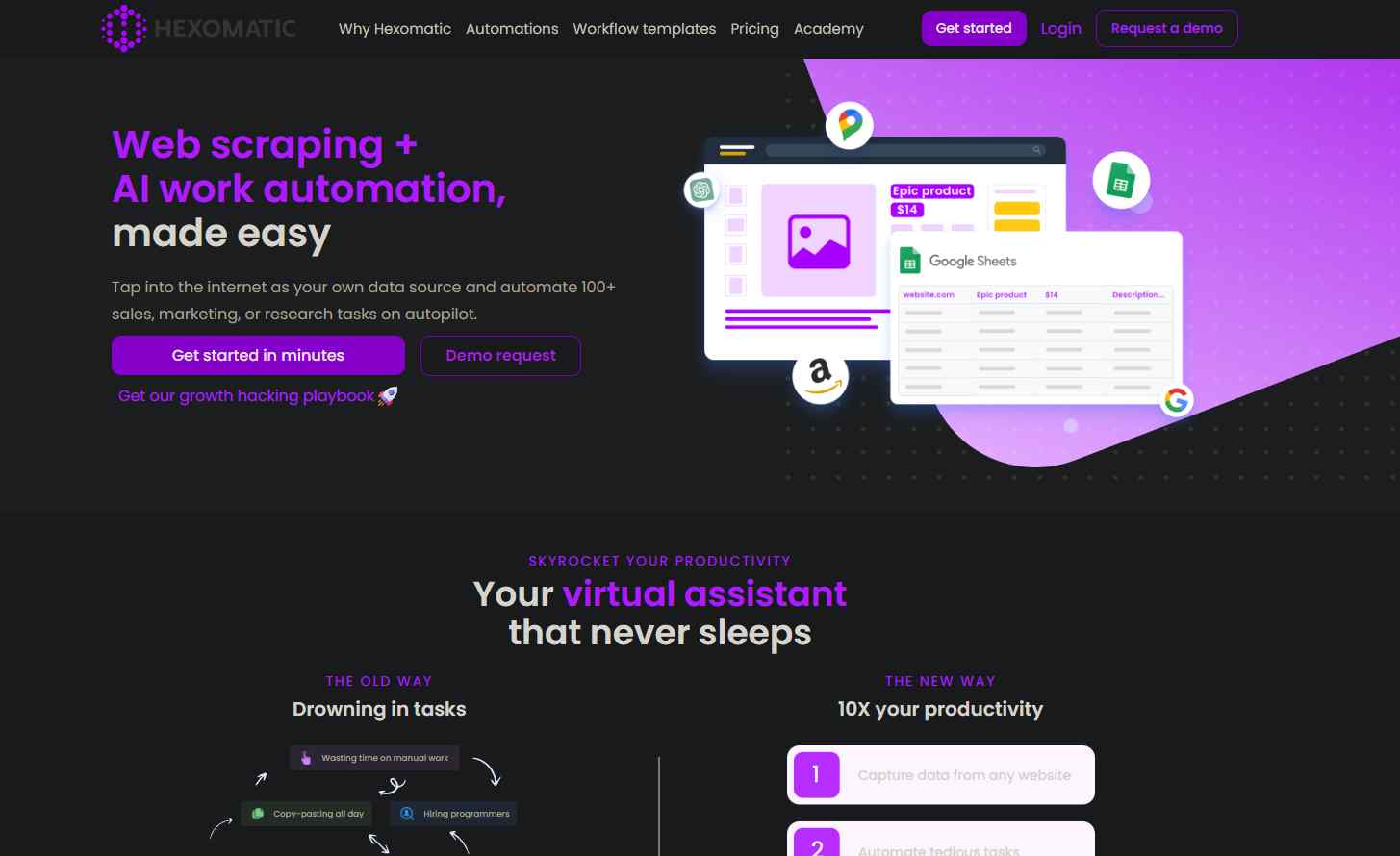

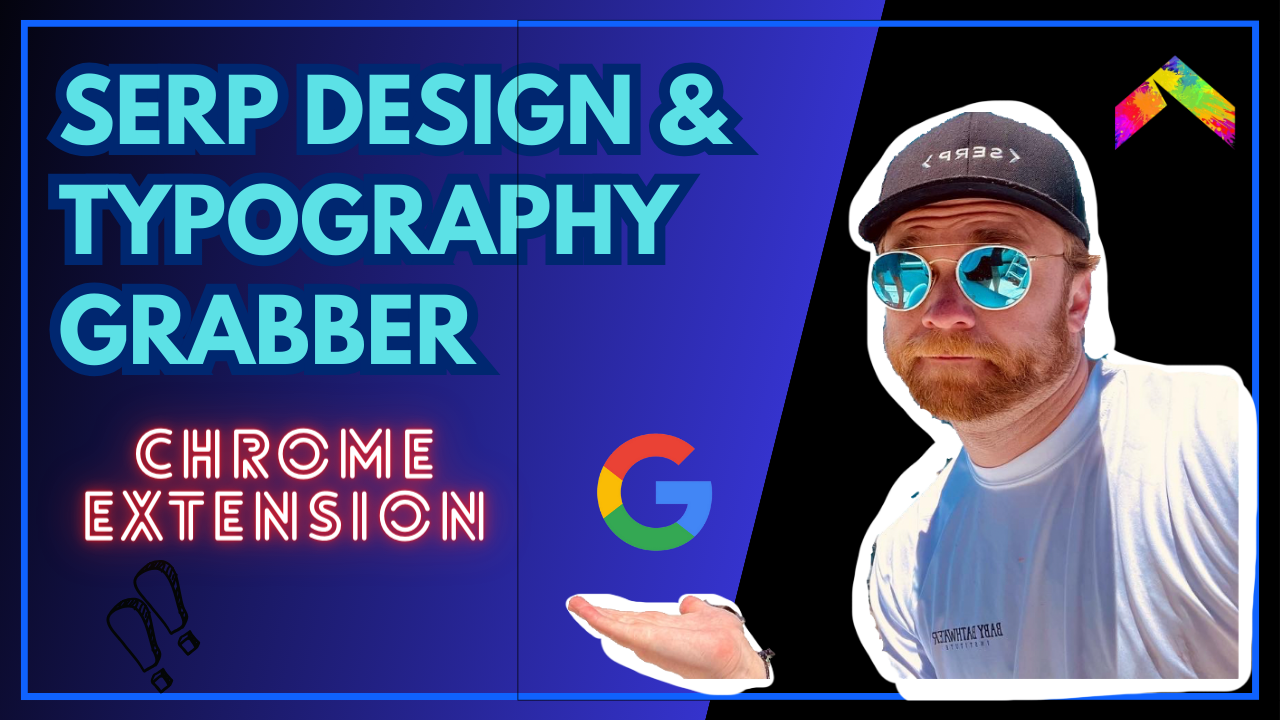

SERP Design & Typography Grabber

I'm shit at design.

I know what I like, but I seem to be first, and then I can never explain it properly to any…

SERP - Medium Clapper Chrome Extension

Add +50 claps to Medium.com Articles in 1-click w/ our Google Chrome Extension | SERP Clapper

Linkly

Create simple, beautiful and branded link trackers with smart redirects, retargeting pixels, QR codes and more.

FineShare Singify

Transform your favorite songs into 100+ different high-quality singing voices anytime, anywhere.

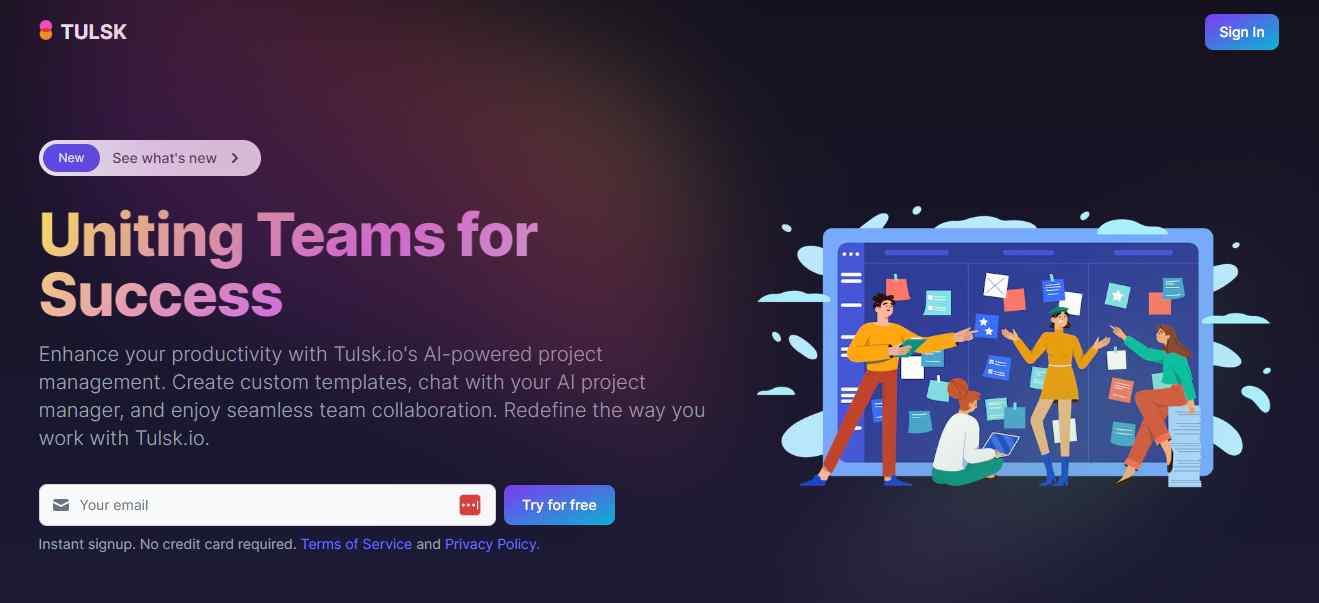

Tulsk

Create custom templates, chat with your AI project manager, and enjoy seamless team collaboration.

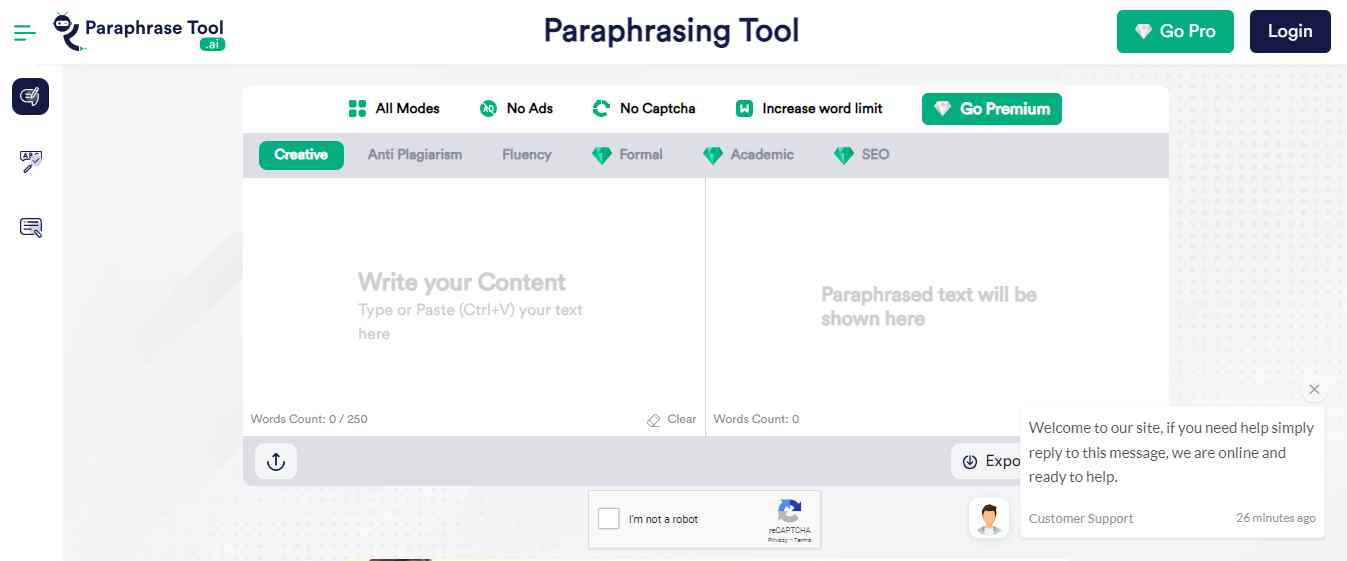

Paraphrasetool.ai

The most advanced AI powered paraphraser to rewrite sentences, paragraphs, and full length articles within seconds.

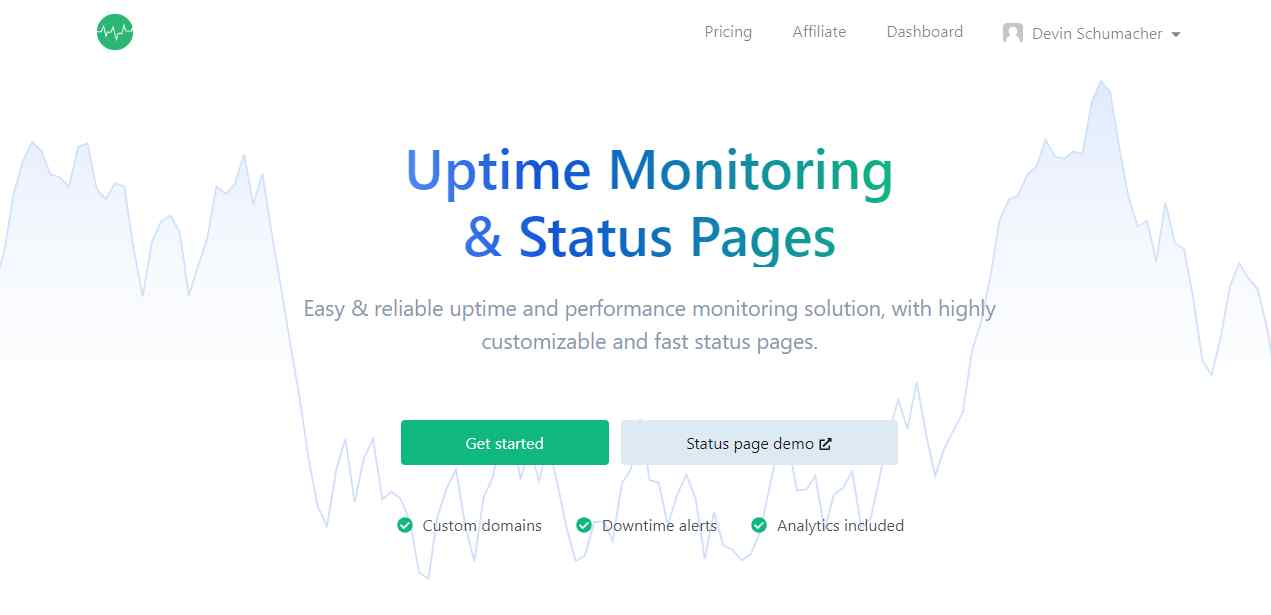

Uptime System

Easy & reliable uptime and performance monitoring solution, with highly customizable and fast status pages.

ChannelMAX

Amazon Repricer Real Time

BuyBox Maximization, Business Pricing, Private Labels, and More.

LinkSpree

Organize, access, and share your favorite websites with LinkSpree - The ultimate link management platform.

AidChat

Revolutionize Interactions, Boost Efficiency, Delight Customers .Train Your Own AI Chatbot using ChatGPT for Smarter, Personalized Customer Support.

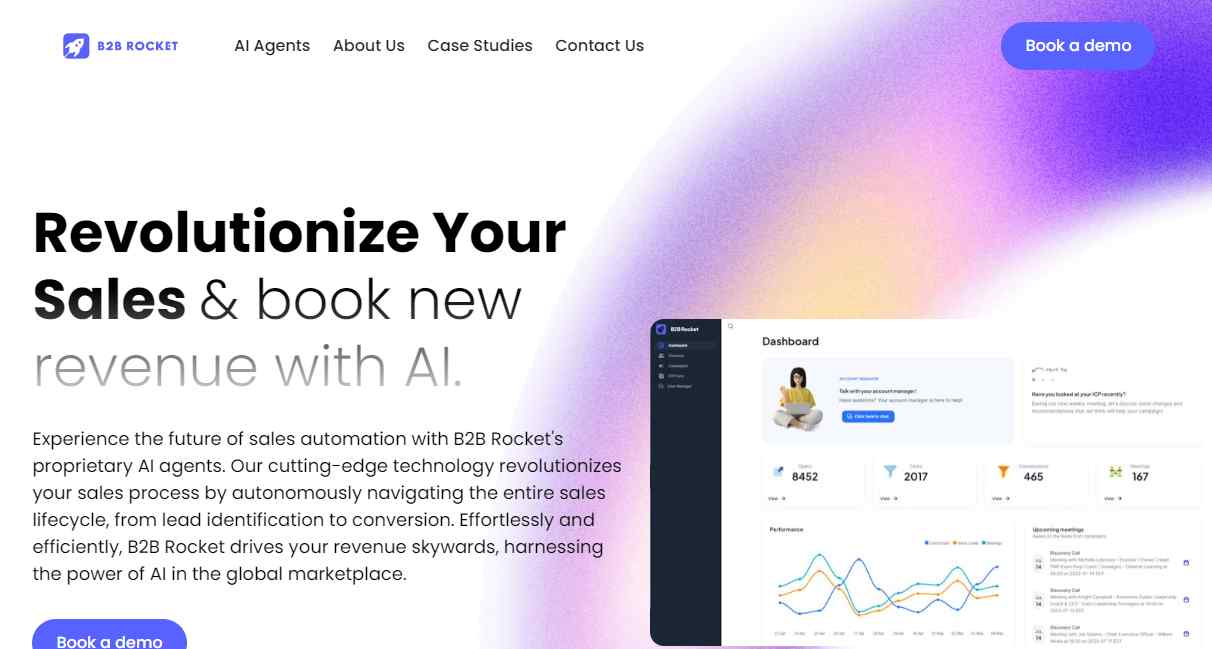

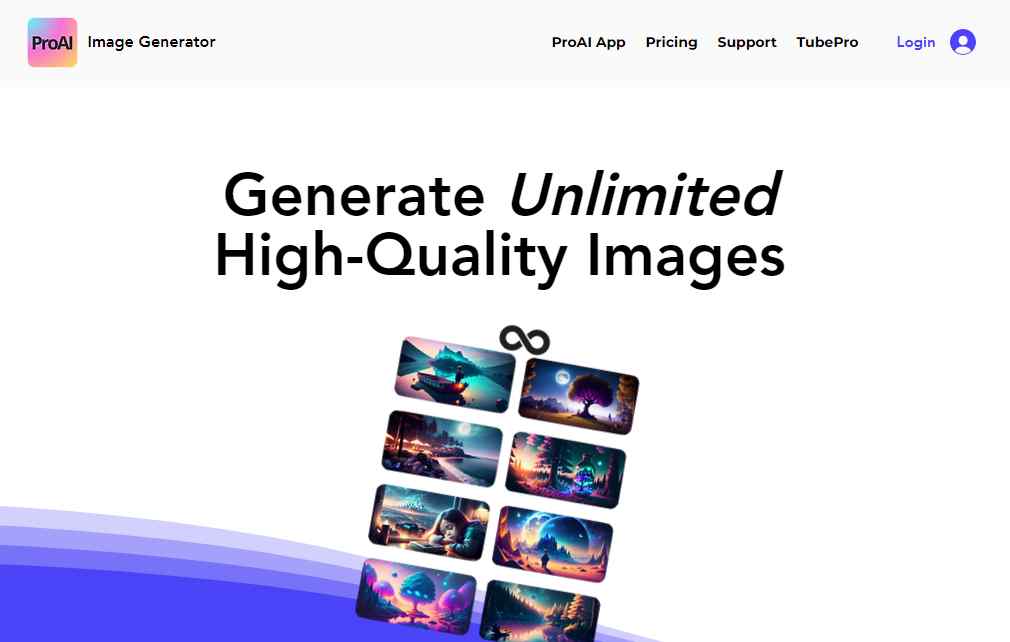

ProAI Image Generator

Elevate your creativity as ProAI transforms ordinary text into extraordinary visual wonders.

Auto Seduction AI

Get 1 to 4 dates a week with perfect conversation starters and personalized messages.

FineShare Online Voice Changer

Helping people create and share inspiring content on any platform and device.

Predis.ai 2.0

Predis.ai 2.0 is an AI-powered predictive analytics tool that offers a range of solutions to help businesses gain insights from their data. With…